aphexii

500+ Head-Fier

- Joined

- Oct 14, 2005

- Posts

- 723

- Likes

- 11

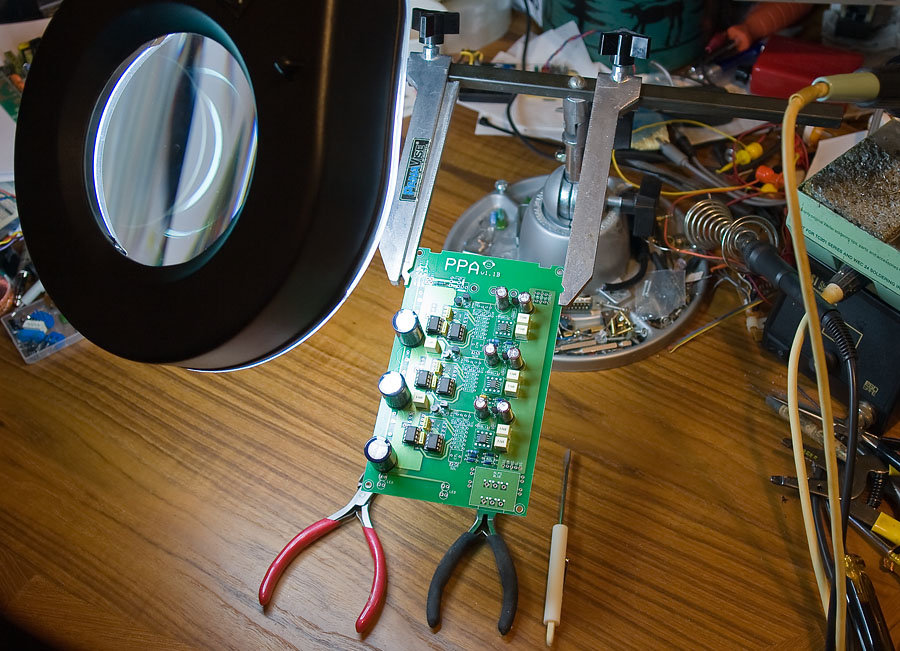

As I build my mini3, the unsteadyness of my hands is really starting to bother me. Its not noticable very much in everyday usage, but when I'm trying to solder tiny parts, it really becomes a problem.

Any suggestions on how to solder with shaky hands? It was bothering me so much I accidentally soldered my LED on backwards when I wasn't paying attention

Any suggestions on how to solder with shaky hands? It was bothering me so much I accidentally soldered my LED on backwards when I wasn't paying attention