PantsUK

New Head-Fier

- Joined

- Jan 13, 2017

- Posts

- 44

- Likes

- 23

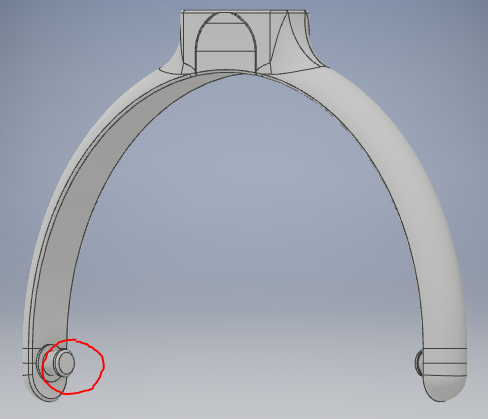

After a lot more of experimenting with the parts antdroid sent me I've been able to finish the design. These are almost 1:1 compared to the original but a little bit wider to reduce stress on the plastic. I've added pins to align the two parts while glueing and after sanding and rubbing it with some acetone they are able to get perfectly smooth. I'm going to get some finer sandpaper and finish it off with some more acetone but I wanted to share these pictures for now.

Before glueing..

After glueing.

After sanding for 15 min and rubbing it with acetone for 5 min. (original on top)

If you want the parts to do it yourself I'll ask €10,- plus shipping which can be done in an envelope. This will require you to use some cutting pliers to snip out the metal pivot from your original yoke, do some slight adjustment to the yoke to get it to fit perfectly, glue the two halves together and sand/smooth the parts if wanted. For €17,50,- plus shipping I will do this for you (which I think is cheap considering it's a 1-2h job plus supplies).

Where do I send the money??.? Mine just broke after 5 days of wearing them 400i though. Have you considered using shapeways as then people can order directly, fit and finish is already done, you can use different material types even metal, and you still get a profit kick back? I’m getting a new set from hifiman but I’d like to have a better quality backup for when the warranty is out.

I tried glueing mine when they cracked but that didn't really hold up since glue is usually a brittle spot. I think glueing and the using a strip of metal on the inside with epoxy could work.

I tried glueing mine when they cracked but that didn't really hold up since glue is usually a brittle spot. I think glueing and the using a strip of metal on the inside with epoxy could work.