- Joined

- Oct 14, 2013

- Posts

- 28,339

- Likes

- 32,164

How to disassemble 2Max

Simpler MAXW1-MAXW2 modifications is up

New MAXEX recipe is up <== Click on Me

MAXEX sound impressions and evaluation can be found here

DX228EX Sound quality can be found here by @edwardsean :

Disclaimer: by modifications and tinkering with your device, your warranty will be voided, and there are devastating risks of permanently damaging your device. Only proceed if you are seeking for the performances with no boundaries, and that you can swallow the cost of it like a man wearing his pants. You have been warned***

**Please, with due respects to any technician within the US or from other countries. If you follow this guide and perform labor, do not charge unreasonable pricing as the developments and tuning of this modifications belong to us, the enthusiasts here on the forum, and mainly the people mentioned in this article**

Amp8-EX can be used on dx150 or also the upcoming dx220

**Also, for Titanium DX200, there is no need to upgrading the regulator**

EX name was realized after observing the sound and the works that was done into it: it stands for

EX-treme Fidelity and EX-treme Modifications

There are 3 parts to this modification

The parts needed for this

Part 1: hardware

https://www.mouser.com/ProductDetail/595-LP5907MFX-3.3NPB

2x of these, buy 4x for spare

Special thanks to @bden59 for looking up for an upgraded regulator with better power dissipation, higher rejections and lower Noises (regular dx200)

https://www.mouser.com/ProductDetail/80-T543B107K010TE150

12x of these, you buy 14X if spares are needed.

https://www.mouser.com/ProductDetail/80-T527I476M10ATE200

7x of these , buy 10x or so for spares

https://www.mouser.com/ProductDetail/80-T527I226M10ATE200

10x of these, buy 12x for spares

https://www.mouser.com/ProductDetail/80-T543B227K6AHW35

3x of these, buy 4x for spares

https://www.mouser.com/ProductDetail/647-RNE1C471MDN1PX

1x of this, 2 for spares

Part 2: Noises suppression

https://www.mouser.com/ProductDetail/810-IFM10M25BB300200

The noises suppression is applied to eliminate the digital noises that plagues us, the digital music world. It can be widely used on other systems as well. However, thanks to DX200 as a platform and a fellow member @chaiyuta , I found this a Vital modification not only for DX200, but for many other players out there.

The processing:

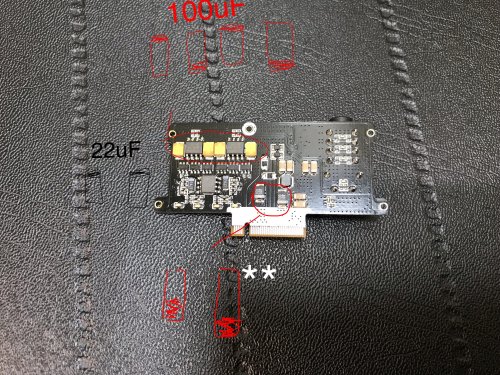

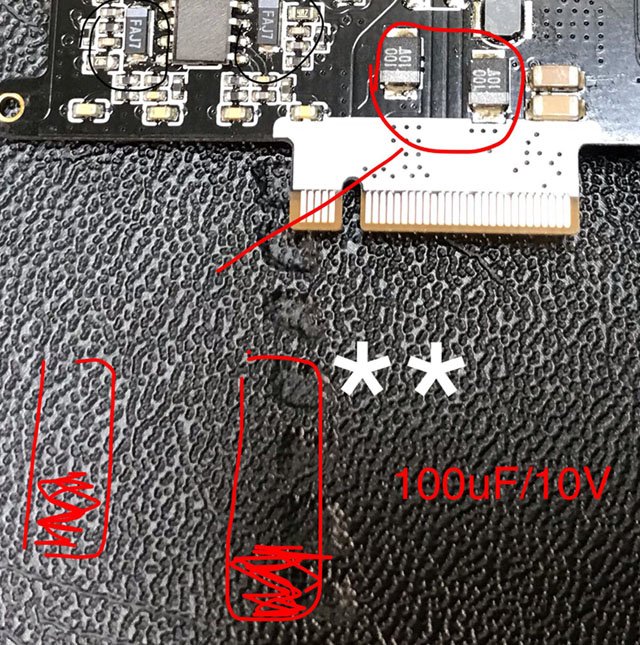

Please bare with me and my horrible hand drawing here. Just have these pictures printed out or in front of you and follow it

On the Amp8 module, and the Main body, the ** takes a little more heat

Main body Hardware

To open up the shield on DAC-IC, please be very careful to lift up with tweezers and do not bend anything

Follow Alex guide to disassemble your Dx200, ribbon Cables connectors has a flip lock that need to be flipped up before you can pull out or insert it back in (then lock)

https://twister6.com/2017/07/05/inside-the-dx200-literally/

*updated first picture with regulator to update as in Blue indicators*

Amp8 Hardware: *unlike Amp8W*, the EX, No MLCC will be used, and No Bi-Cap

Main body Part 2: noises suppression cover main IC, DAC Chips is personal preferences (optional), I use it, and the WiFi antenna back

Do take notice that all trimming of the sheets have to be clean off and away from the pcb on both of the main body and the Amp. If it is laying in between any thing, it could cause short circuit

Amp8 noise suppression

Apply the sheets at the square regulator before putting in 470uF Nichicon

The rest can be applied after the modification is done. Coil inductors can be covered too, but optional, I left it out

Simpler MAXW1-MAXW2 modifications is up

New MAXEX recipe is up <== Click on Me

MAXEX sound impressions and evaluation can be found here

DX228EX Sound quality can be found here by @edwardsean :

Disclaimer: by modifications and tinkering with your device, your warranty will be voided, and there are devastating risks of permanently damaging your device. Only proceed if you are seeking for the performances with no boundaries, and that you can swallow the cost of it like a man wearing his pants. You have been warned***

**Please, with due respects to any technician within the US or from other countries. If you follow this guide and perform labor, do not charge unreasonable pricing as the developments and tuning of this modifications belong to us, the enthusiasts here on the forum, and mainly the people mentioned in this article**

Amp8-EX can be used on dx150 or also the upcoming dx220

**Also, for Titanium DX200, there is no need to upgrading the regulator**

EX name was realized after observing the sound and the works that was done into it: it stands for

EX-treme Fidelity and EX-treme Modifications

There are 3 parts to this modification

The parts needed for this

Part 1: hardware

https://www.mouser.com/ProductDetail/595-LP5907MFX-3.3NPB

2x of these, buy 4x for spare

Special thanks to @bden59 for looking up for an upgraded regulator with better power dissipation, higher rejections and lower Noises (regular dx200)

https://www.mouser.com/ProductDetail/80-T543B107K010TE150

12x of these, you buy 14X if spares are needed.

https://www.mouser.com/ProductDetail/80-T527I476M10ATE200

7x of these , buy 10x or so for spares

https://www.mouser.com/ProductDetail/80-T527I226M10ATE200

10x of these, buy 12x for spares

https://www.mouser.com/ProductDetail/80-T543B227K6AHW35

3x of these, buy 4x for spares

https://www.mouser.com/ProductDetail/647-RNE1C471MDN1PX

1x of this, 2 for spares

Part 2: Noises suppression

https://www.mouser.com/ProductDetail/810-IFM10M25BB300200

The noises suppression is applied to eliminate the digital noises that plagues us, the digital music world. It can be widely used on other systems as well. However, thanks to DX200 as a platform and a fellow member @chaiyuta , I found this a Vital modification not only for DX200, but for many other players out there.

The processing:

Please bare with me and my horrible hand drawing here. Just have these pictures printed out or in front of you and follow it

On the Amp8 module, and the Main body, the ** takes a little more heat

Main body Hardware

To open up the shield on DAC-IC, please be very careful to lift up with tweezers and do not bend anything

Follow Alex guide to disassemble your Dx200, ribbon Cables connectors has a flip lock that need to be flipped up before you can pull out or insert it back in (then lock)

https://twister6.com/2017/07/05/inside-the-dx200-literally/

*updated first picture with regulator to update as in Blue indicators*

Amp8 Hardware: *unlike Amp8W*, the EX, No MLCC will be used, and No Bi-Cap

Main body Part 2: noises suppression cover main IC, DAC Chips is personal preferences (optional), I use it, and the WiFi antenna back

Do take notice that all trimming of the sheets have to be clean off and away from the pcb on both of the main body and the Amp. If it is laying in between any thing, it could cause short circuit

Amp8 noise suppression

Apply the sheets at the square regulator before putting in 470uF Nichicon

The rest can be applied after the modification is done. Coil inductors can be covered too, but optional, I left it out

Attachments

Last edited:

! Or dx150

! Or dx150 But ...

But ...