assassin10000

Headphoneus Supremus

I don't like K's Bell (cheap version). The comfort is great, but due to the lack of back vent, there is almost no bass. NiceHCK EB2 seems to have probably the best vent system

but the driver is not at the same level as the competition. Moondrop has too large back holes but I don't see how it looks inside. Probably not look like concepts below

It's interesting how many solutions can be done here.

The Little Bell (cheaper) and Bell Ti (TOTL) both have the 3 side vents on both sides. The LB has lots of mid bass and lower mids, its a very warm bud.

The LB has foam over all 6 holes. If one was uncovered it may be the right amount of airflow. Just a matter of tuning, like every other bud.

__________________________

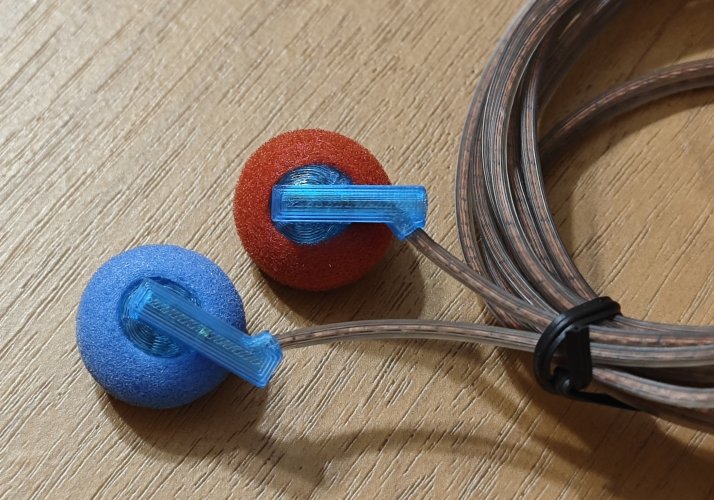

After 4 months my set of MMCX ends showed up, so I could finally make a straight down cable.

Yesterday my second set of these slightly oversized PK shells also arrived, so I could finally compare them.

Modding the shell and using short MMCX connectors leaves me with almost the same length as the original. So they can still be used cable down with no issues.

Not looking forward to modding more shells, it's time consuming and tedious lol.

Last edited: