WallofHooligans

100+ Head-Fier

- Joined

- Feb 8, 2017

- Posts

- 331

- Likes

- 136

Hello, my dudes. I figured I would detail one of my goings-ons and ask for a bit of feedback.

Recently, I spied a heavily beaten and battered Stanton Dynaphase Sixty on the ebay. Now, I already own a pair in great condition and I absolutely love it. There's just something about the huge soundstage and sapphire coloration that tickles my fancy. Not to mention the old Stanton logo has it's own beauty, and the idea of a two-way headphone really piques my interests. I've become almost entirely an orthodynamic/planar magnetic purist, but these Dynaphase cans just activate my almonds, if you know what I mean. They get my noggin' joggin'.

Let me start by showing off what we're dealing with here so you can see what square we're starting at before we play.

OOF, that's a haggard pair of cans. But they are even worse than they look from this image. Here's the skinny on some smaller details.

Yep, those are the earpads.... but with the padding and the top layer pulled out entirely! Ripped asunder like a dry potato through a table saw! There's a hidden bonus here- upon pulling off the useless earpad bits, I found an entire edge of crushed plastic contained in it. There's a chunk of flat plastic missing from around 30% of the circumference. That means that it's impossible to get a seal, and the sharp edges pose a threat to new earpads. I'm not sure how to rebuild it, but I'm much too stubborn to cut my losses!

Here's the cable and plug. It's not the standard termination, and the part itself doesn't seem to close correctly. It's a bit rusted and whatnot. The cable isn't supposed to be such a dusky blue, and all of the heatshink strain reliefs are missing. I'm not too worried about these bits, I plan on doing something fancy as a replacement.

Yep, the headband is totally ruined too. The original (admittedly sort of crappy) pleather is totally bound from one end to the other in sticky old electrical tape. I didn't even think about this one, I cut the sucker off end to end and trashed it. The insides were exposed and the foam had a bit of decomposition going on, which is why they probably bound it in tape. Yuck. Strangely though, these things don't have the usual "oh they've been in grandpa's basement for 40 years" smell. I wonder what these things have seen. The last owner had done a few quick fixes to these, a super glued strain relief, the non standard termination and bound headband, not to mention the slight fading of the blue plastic on the upper ends of the cups... I imagine that these must have been well used for many years. I'm going to do my best to reanimate this puppy, and modify them to my liking.

Edit*** These first pictures are shamelessly stolen from the ebay seller***

Recently, I spied a heavily beaten and battered Stanton Dynaphase Sixty on the ebay. Now, I already own a pair in great condition and I absolutely love it. There's just something about the huge soundstage and sapphire coloration that tickles my fancy. Not to mention the old Stanton logo has it's own beauty, and the idea of a two-way headphone really piques my interests. I've become almost entirely an orthodynamic/planar magnetic purist, but these Dynaphase cans just activate my almonds, if you know what I mean. They get my noggin' joggin'.

Let me start by showing off what we're dealing with here so you can see what square we're starting at before we play.

OOF, that's a haggard pair of cans. But they are even worse than they look from this image. Here's the skinny on some smaller details.

Yep, those are the earpads.... but with the padding and the top layer pulled out entirely! Ripped asunder like a dry potato through a table saw! There's a hidden bonus here- upon pulling off the useless earpad bits, I found an entire edge of crushed plastic contained in it. There's a chunk of flat plastic missing from around 30% of the circumference. That means that it's impossible to get a seal, and the sharp edges pose a threat to new earpads. I'm not sure how to rebuild it, but I'm much too stubborn to cut my losses!

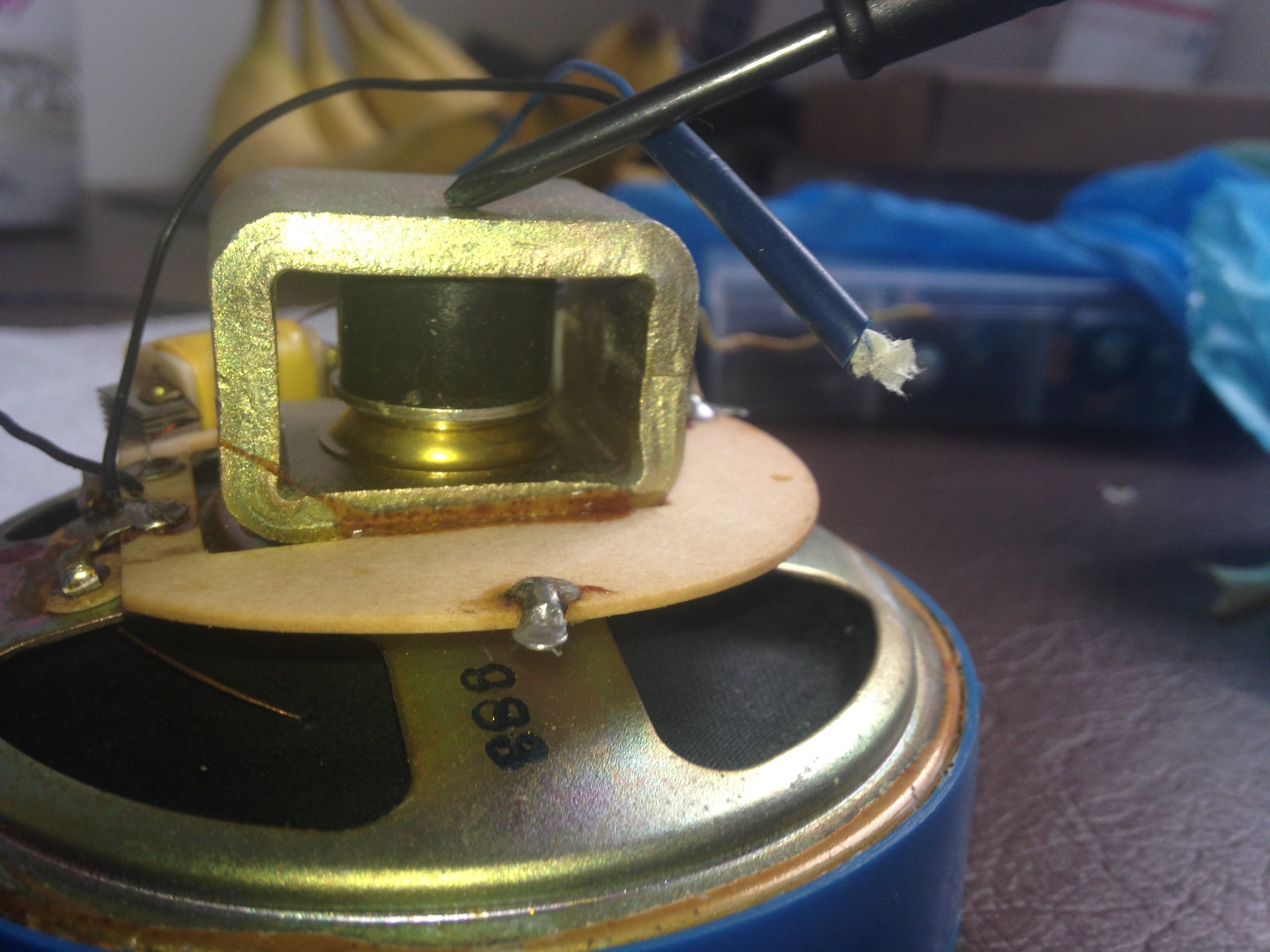

Here's the cable and plug. It's not the standard termination, and the part itself doesn't seem to close correctly. It's a bit rusted and whatnot. The cable isn't supposed to be such a dusky blue, and all of the heatshink strain reliefs are missing. I'm not too worried about these bits, I plan on doing something fancy as a replacement.

Yep, the headband is totally ruined too. The original (admittedly sort of crappy) pleather is totally bound from one end to the other in sticky old electrical tape. I didn't even think about this one, I cut the sucker off end to end and trashed it. The insides were exposed and the foam had a bit of decomposition going on, which is why they probably bound it in tape. Yuck. Strangely though, these things don't have the usual "oh they've been in grandpa's basement for 40 years" smell. I wonder what these things have seen. The last owner had done a few quick fixes to these, a super glued strain relief, the non standard termination and bound headband, not to mention the slight fading of the blue plastic on the upper ends of the cups... I imagine that these must have been well used for many years. I'm going to do my best to reanimate this puppy, and modify them to my liking.

Edit*** These first pictures are shamelessly stolen from the ebay seller***

Attachments

Last edited: