bcowen

Headphoneus Supremus

Any of the 1950's production dates sound great to me. The ribbed plate versions sound just a bit better than the smooth plates, but the difference isn't huge. I wouldn't pay a huge premium for a ribbed versus smooth plate one, but if you run across some '55 or earlier for a decent price, they're worth the grab (IMO).The oldest 6H8C i have are from 58 they really sound great, I also have some from 64,66 which are frankly not so bad but sold all the 70' for almost nothing. I also have a pair from 0880 for the fun

Those tubes are very stable once hot (no hum, no rfi, autobias of CTH never drop).

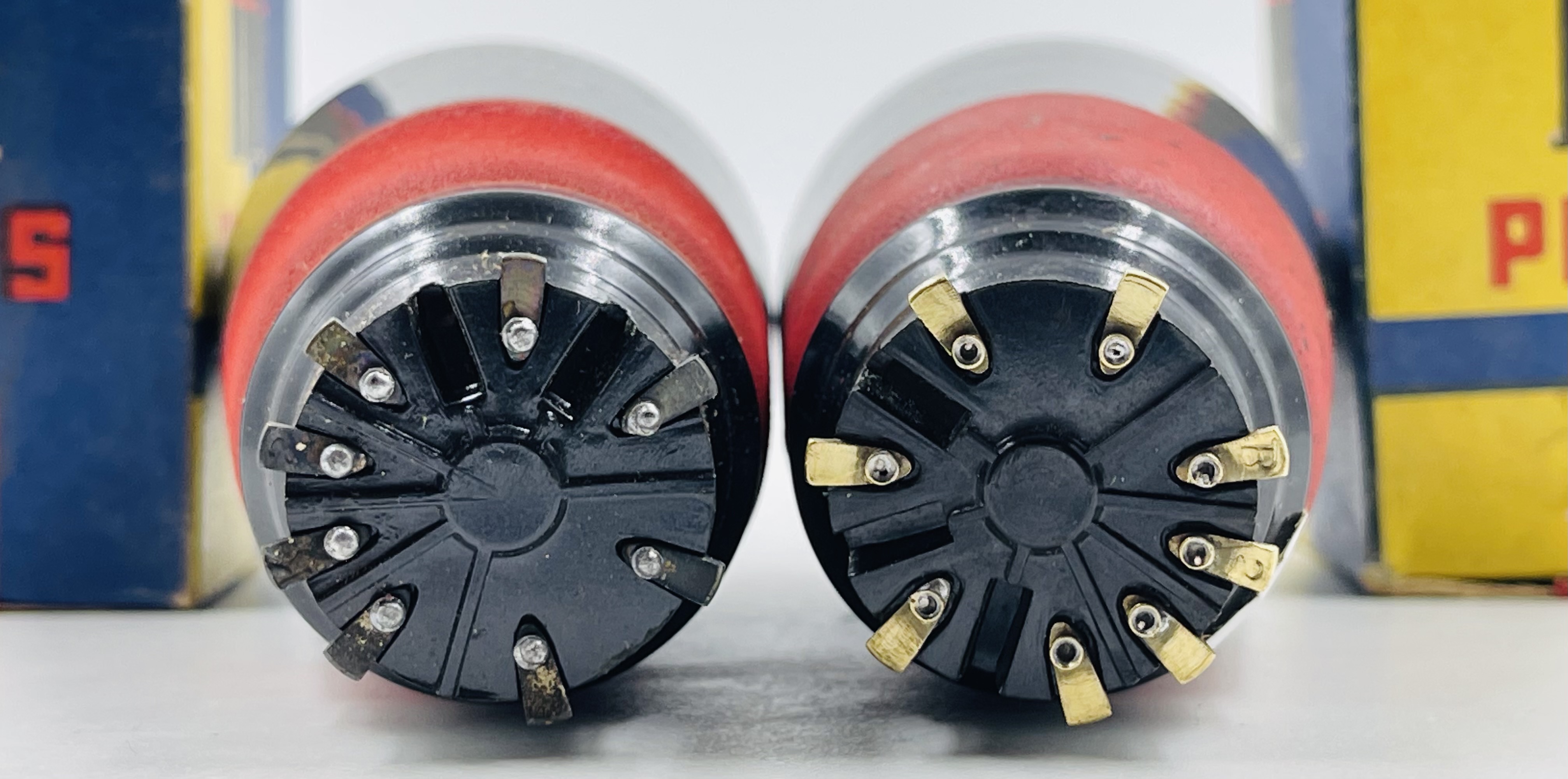

The one with silver paint on the left is from 58, the one on the right from 67..

1953 with the ribbed plates: