DBaldock9

Headphoneus Supremus

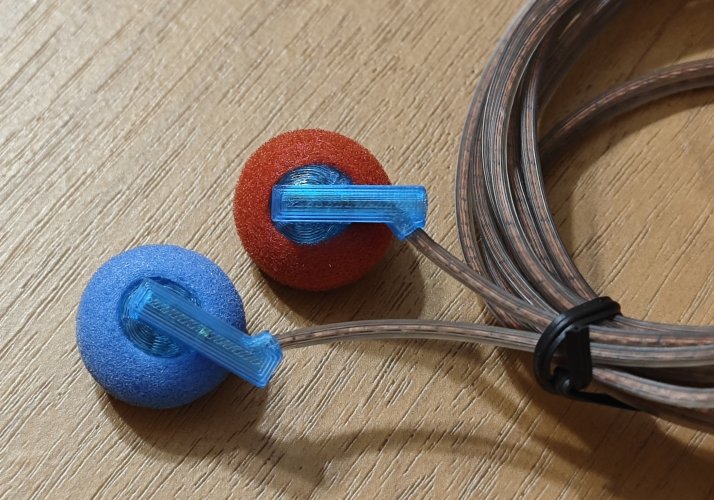

Every earbud driver I see has one connector marked with paint/ink.

The drivers have polarity, one contact is +/positive and the other is -/negative.

In all earbud drivers I've seen:

The (+) contact is marked with paint/ink and connect to the Red wire (R) or the Green wire (L).

The (-) contact is unpainted/unmarked and connect the ground wires.

Something interesting is my TY HI-Z 32, doesn't have the paint/marks on the same side of the driver.

Do you think they build the driver and only after that they somehow measure and mark the polarity?

Back when I was building speakers, and working with larger, bass & midrange drivers, I could touch the cone while checking the resistance, and feel which way it moves with the Ohmmeter's DC voltage being applied.

With small drivers, where you can't really feel them move, you may have to hook a microphone to an oscilloscope, and look to see whether you get a rising or falling pulse when the Ohmmeter's DC voltage is applied.

Last edited:

This is the thing I am mostly in doubt about, how much to use?

This is the thing I am mostly in doubt about, how much to use?