Can you provide more information on what you are trying to do and what the cable is connecting? Is this SE or Balanced?

For some applications using a common ground between L/R is okay. For others, NOPE.

I do not think you will find sleeving any easier as the vast majority use the "inchworm" technique that I guess you used. Only other way is if the sleeve is much larger than the cable and then you have a ugly sleeved cable with wrinkles.

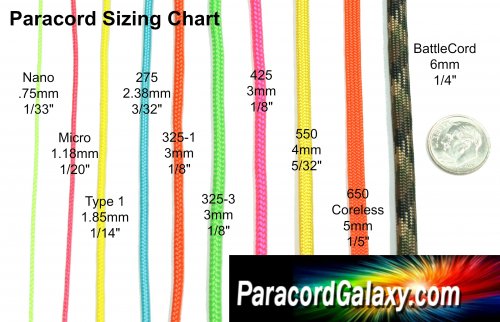

If you want a different quad cable, unstripped Mogami 2799 fits into 550 paracord for a total OD of about 4.2mm. Its a pretty tight fit.

For different sleeving...If 1/4 Paramax doesn't fit that cable, you have to go up to techflex-style sleeving. I do not know of any larger size paracord than "paramax". Not sure the thickness of TechFlex compared to ParaMax. Also, the ParaMax from Paracord Planet is almost exactly 1mm thick, unexpanded. After sleeving, I would expect the sleeve to become thinner. I would have expected that your final OD would be just under 8mm (6 + 0.98 + 0.98 or something)... Maybe the paracord from SGT is thicker? I have never used paracord from SGT before.

I just tried to squeeze Canare L-5CFW (0.300") into ParacordPlanet Paramax (0.250") and it was an utter fail. Waiting for 3/8" techflex to come in and see how that fits.